What Kind of Fabric Works Best?

The clothes we wear are made of all sorts of materials, and the type of custom print we can achieve is determined by what that material is. Is it natural or synthetic? Is it cotton or a cotton blend? Polyester, huh? Maybe it’s one of those fancy tri-blend types. We can print your design on any of these fabrics and more, but some printing methods are more suitable than others when it comes to making your perfect custom t-shirt.

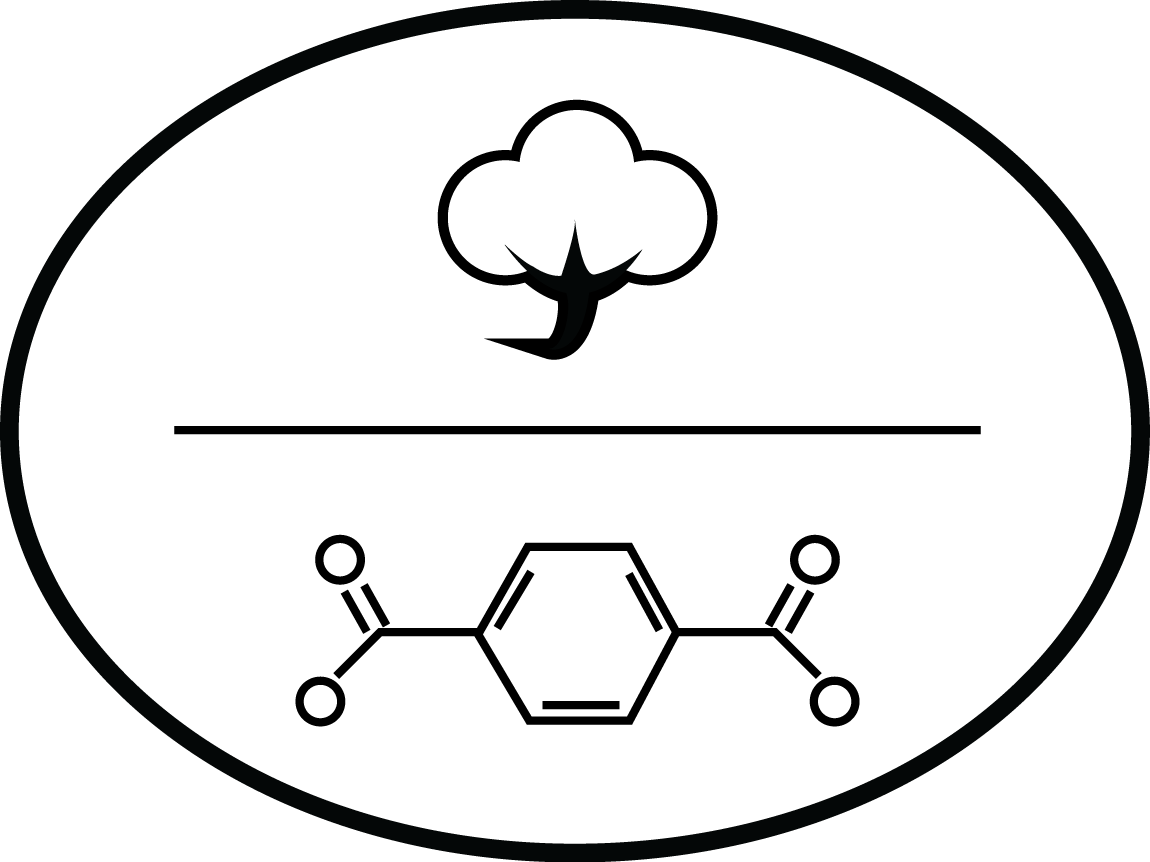

Cotton

Common, Comfortable, and Cool

Cotton, coming directly from nature, has a, well, natural comfort to it, offering a soft, breathable feeling upon donning said fabric. The structure of the fabric allows air to pass through the fibers, making for a literally cool wear in warm weather. It’s an extremely versatile material that’s been put to use for more than 7,000 years.

Among cotton are a number of varieties of which garments are made from. The two main types of cotton are basic cotton and ringspun cotton. Basic cotton offers a good value of a cheap, durable shirt. Ringspun cotton is a higher quality material created by spinning the cotton fibers into softer, more refined strands, offering a smoother feel at a higher price.

The main downside to cotton is that cotton tends to wrinkle and, infamously, shrink when washing. Why does cotton shrink? When a cotton garment is fabricated, it has a certain tension applied to it during construction. Washing it releases that tension, and the cotton fibers shrink down to their natural size.

Printing on Cotton

Regardless of the type of cotton, the material is the industry standard for textile printing. The fibers naturally absorb the ink printed on it, making for an easy transfer. If you’re in need of cool custom cotton shirts, the material works well on all our printing services.

Polyester

Man-Made Miracle Material

Polyester is a synthetic material, meaning man was brave enough to engineer a fabric to achieve certain superiorities to a natural fabric like cotton. Synthetic materials tend to offer all sorts of benefits, such as resistance to shrinkage and wrinkles, and durability. You’ll often see manufacturers touting polyester garments and their oh-so-desirable moisture-wicking feature that draws moisture and sweat away from the body, bringing it to the surface of the fabric for quick evaporation, and keeping the fabric itself dry. It’s these characteristics that make polyester ideal for athletic wear. These types of shirts are often labeled “Performance Shirts.”

Printing on Polyester

The scientists developing polyester didn’t necessarily have custom printing in mind when they created it. Polyester offers some unique challenges when it comes to applying a custom design to it. Synthetic materials have a low heat-tolerance, making them susceptible to dye migration during the heat curing process of a screen printed design. This results in the fabric’s dye bleeding into the ink printed on top of the shirt. That great moisture-wicking feature also inhibits the use of water-based inks since the material is made to, you know, repel water.

These challenges can be overcome with special considerations. While Direct to Garment is usually a no-go for printing on polyester, today’s screen printing technology has brought us additives and low-bleed inks that can keep dye migration to a minimum. There’s also a way to customize a shirt without having to worry about any of that stuff, and that’s Heat Transfer Vinyl. We can apply vinyl to synthetic shirts with no problem, so if you’re interested in personalizing a polyester jersey or something like that, Heat Transfer Vinyl is the way to go.

Polyester-Cotton Blend

Polyester-Cotton Blend

The Best of Both Worlds

If you want the benefits of cotton and polyester, naturally you’ll want to blend the two together! With this type of fabric, you can get a reasonably soft, breathable and durable shirt that’s low-maintenance and resistant to wrinkles and shrinking. You’ll find this type of material in all sorts of clothing, from polos to sports jerseys.

Printing on Polyester Cotton Blend

Poly-cotton blends set similar challenges to 100% polyester when it comes to printing. It really depends on the percentage of cotton versus polyester in the garment. The more cotton, the better. A “50/50” blend means 50% cotton/50% polyester, but the percentages can vary in favor of one material over the other.

We can take special considerations for Screen Printing onto poly-cotton blends. DTG might even work depending on the cotton content of the shirt. But, again, Heat Transfer Vinyl is usually your best bet for any sort of synthetic or synthetic-blend material.

Tri-Blend

Fashionable, Flexible, and Fun

Okay, combining cotton and polyester is pretty cool, but how about adding a third material to the mix? Tri-blend clothing is a relatively recent innovation, first hitting the fashion scene in 2006. Tri-blend garments tend to be made up of 50% polyester, 50% cotton, and 25% rayon. The polyester element makes it durable, the cotton makes it comfortable, and the rayon makes it fit well with its exceptional drape. The result of mixing these 3 materials is an incredibly soft but resilient fabric.

Printing on Tri-Blend

Since tri-blend garments are made of 3 different materials, we have to take into account the ways in which those materials react to our printing processes. Tri-blend shirts present similar obstacles to synthetic fabrics when it comes to screen printing. The rayon in particular has a very low heat resistance, so prints tend to be applied with thin ink layers and “wet-on-wet.” This often results in a vintage, washed-out look, which may actually be desirable. It not only creates a soft, unique look, but it also retains the lightweight nature of the tri-blend fabric. I mean, if you’re going through the trouble to introduce rayon to the mix, you might as well keep its notable draping function.

Tri-blends usually don’t come in a solid color. They generally have a dappled, heather-like look to them, which, when paired with that “vintage” printing style, makes them extremely fashionable.

Further Fabric Terminology

When shopping for shirts, you’ll eventually come across some terminology that you might not be familiar with. Here’s some of the most common terms you’ll see when comparing shirt styles.

Jersey Knit

Not to be confused with a sports-style jersey, Jersey is a type of knit fabric that most t-shirts are made of. The name comes from Jersey of the Channel Island where the first Jersey knit materials were produced.

As a result of how the knit is constructed, jersey knits are flat with little texture to them. Jersey knit is used in many different types of clothing including t-shirts, polos, and dresses. It’s the material you think of when you think of an ordinary t-shirt. It’s light, flexible, and smooth, making it ideal for custom design printing.

Pique Knit

The Pique knit is on the opposite side of Jersey. While Jersey has a relatively smooth surface, Pique knits have a ribbed-like texture, giving it a stiffer body. Pique knit shirts are sturdier, and the knit provides additional ventilation for warm weather.

The material is most commonly associated with polo shirts. They’re the more textured polos you might’ve seen and are considered more formal than Jersey knit polos.

Printing on pique knit material is a little more difficult than Jersey. Custom prints don’t show as much detail due to the ribbed texture of the knit.

Baby Rib

Often found in women’s style clothing as well as collars on jersey knit shirts. Unlike “jersey” and “pique,” whose meanings aren’t exactly obvious, a rib knit is just what it sounds like: a ribbed texture (not sure where the “baby” part comes from, though).

Baby ribbed knits stretch easily without warping the original shape of the shirt, which is why it’s often used to finish sleeves and necklines, areas of the shirt that a prone to stretching during normal wear.

Preshrunk

In order to minimize the shrinkage that occurs when washing certain fabrics, manufacturers will sometimes “preshrink” them. They place the garments in a machine that pushes the fibers together, replicating shrinking. The garment may still shrink after the first wash, but it will, ideally, be by a minimal amount.

CVC

CVC stands for “Chief Value Cotton.” It’s a polyester cotton blend that leans heavily on the cotton, with greater than 50% cotton composition. They’re very similar in softness to a Tri-Blend fabric, but without the Rayon, making it more affordable and easier to print on.

Heather

Heather clothing is made up of yarns that blend together pre-dyed fibers of different colors. The result is a fabric that is not one solid color but a mix of different shades. The blending of colors can create a very particular look, such as blending black and white fibers to create a heathered grey. Sometimes it mixes synthetic and natural fibers as well.